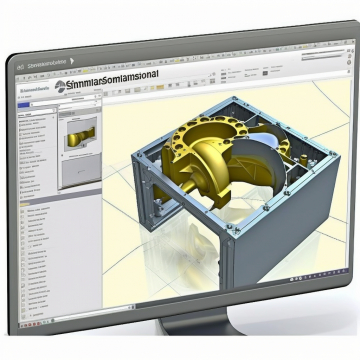

SimWise: Comprehensive Simulation Capabilities for Engineers and Designers

Friday, 19 August 2022SimWise offers an extensive suite of simulation capabilities, enabling users to analyze and optimize their designs effectively:

-

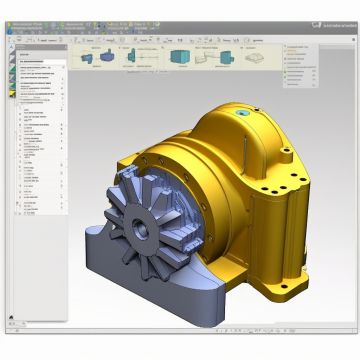

3D Dynamic Motion Simulation: SimWise allows users to model complex interactions such as 3D contact, gears, actuators, and connections between parts. SOLIDWORKS mates are automatically converted to motion joints, ensuring seamless integration.

-

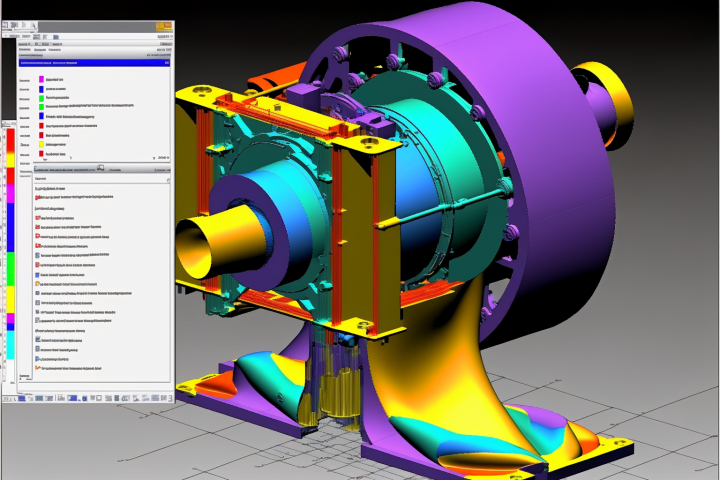

Finite Element Analysis (FEA): SimWise supports various FEA types, including static, normal modes, buckling, steady state and transient thermal, and combined structural thermal analyses. This comprehensive approach enables users to analyze their designs under various conditions.

-

Combined Motion and FEA Simulation: This feature combines dynamic forces from motion simulations with other loading conditions, providing a complete stress profile of the design throughout its range of motion. This holistic view helps users optimize their designs for real-world applications.

-

Optimization: SimWise allows users to utilize SOLIDWORKS dimensions, variables, and simulation-specific quantities as optimization parameters and constraints. By running multiple motion, FEA, or combined simulations, users can achieve design objectives such as minimum weight or maximum speed.

-

Co-Simulation with MATLAB/Simulink: SimWise models can be used as plant models in Simulink, enabling control systems modeled in Simulink to control SimWise motion models. This integration allows users to validate their control systems against mechanical models that incorporate real-world physical effects.

-

Fatigue Life Calculations: With the optional SimWise Durability module, users can determine the fatigue life of any part in the assembly. The stress time history calculated by a combined Motion + FEA simulation is used to assess the longevity of components.

By offering a wide range of simulation capabilities, SimWise empowers engineers and designers to thoroughly analyze their creations, identify potential issues, and optimize their designs for performance, reliability, and durability.

SimWise 4D stands as DST's top-tier solution, expertly merging our essential dynamic motion simulation technology with Finite Element Analysis. This powerful combination generates a holistic and versatile tool for designers working on mechanical systems involving moving parts. With its CAD-agnostic capabilities, SimWise 4D effortlessly imports data from a wide range of industry-leading CAD software, ensuring seamless integration and adaptability across various design environments.

Designers frequently face challenges in determining the functionality and durability of their creations without resorting to time-consuming and costly physical prototyping. SimWise 4D addresses these concerns by providing a comprehensive virtual testing platform that allows engineers to evaluate the performance and structural integrity of their designs quickly and economically.

SimWise 4D revolutionizes the design process by offering a user-friendly interface that streamlines the learning curve for new users, enabling them to efficiently harness the software's full potential. The software fosters an intuitive understanding of complex concepts, empowering designers to make informed decisions about their projects.

Through its advanced simulation capabilities, SimWise 4D allows designers to identify and resolve potential issues in their designs early in the development process. This proactive approach saves valuable time and resources by minimizing the need for revisions and modifications in later stages.

By simulating real-world scenarios, SimWise 4D equips designers with the ability to assess and optimize the performance of their creations under various operating conditions. This level of detail ensures that products are not only functional but also robust and reliable, ultimately resulting in higher customer satisfaction and reduced warranty claims.

SimWise 4D's compatibility with leading CAD systems ensures that designers can continue to work with their preferred design tools while benefiting from the added value of advanced simulation capabilities. This seamless integration facilitates a smooth and efficient design workflow, maximizing productivity.

With its comprehensive suite of analysis tools, SimWise 4D enables designers to explore different design alternatives and make data-driven decisions to optimize their creations. This iterative process results in refined designs that meet or exceed performance requirements and minimize potential risks.

In addition to its robust simulation capabilities, SimWise 4D offers powerful visualization and reporting features that allow designers to effectively communicate their findings to stakeholders. This clear presentation of results fosters better collaboration and informed decision-making throughout the product development process.

By leveraging SimWise 4D's advanced features, designers can not only create innovative products but also streamline their development processes, ultimately reducing time-to-market and increasing their competitive edge in the industry.

In summary, SimWise 4D stands as a comprehensive, user-friendly, and cost-effective solution for designers working on mechanical systems with moving components. Its powerful dynamic motion simulation technology, coupled with Finite Element Analysis, addresses critical questions related to functionality and durability, resulting in efficient, optimized designs that stand the test of time.

Using SimWise, the CAD to Simscape Multibody workflow becomes: Key Features

Saturday, 19 February 2022To address these challenges, consider adopting a solution that streamlines the integration of CAD models with Simscape Multibody. Such a solution should provide the following capabilities:

-

Seamless CAD-to-Simscape Multibody Conversion: The solution should enable smooth and accurate conversion of CAD models to Simscape Multibody-compatible formats, preserving essential design information such as geometry, mass properties, and assembly constraints.

-

Model Validation and Debugging: The solution should offer tools to help users quickly identify and resolve any issues in the multibody model, ensuring that it accurately represents the intended design and behaves correctly in simulations.

-

Efficient Model Update Management: The solution should provide a robust method for managing changes to the CAD assembly, allowing users to easily update the Simscape Multibody model without losing any simulation-specific information.

-

Bidirectional Data Exchange: The solution should support bidirectional data exchange between the CAD system and Simscape Multibody, enabling users to incorporate simulation results back into the CAD model for further design optimization.

-

User-friendly Interface: The solution should offer an intuitive, user-friendly interface that simplifies the process of integrating CAD models with Simscape Multibody, reducing the learning curve and increasing overall productivity.

By adopting a solution that streamlines the integration of CAD models with Simscape Multibody, engineers and designers can save valuable time and effort, allowing them to focus on optimizing their designs and ensuring optimal performance in real-world applications.

K2 Archives

K2 User

K2 Content

- Instructor Insights and Academic Endeavors: Interactive Physics in Action Written on Friday, 19 August 2022 07:53

- 3D Dynamic Motion Simulation with Advanced Features Written on Friday, 19 August 2022 07:52

- SimWise: Comprehensive Simulation Capabilities for Engineers and Designers Written on Friday, 19 August 2022 07:51